Iron Ore production in the Pilbara

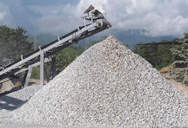

Processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products. This is done by physical processes, which remove impurities by differences in particle density or size gravity or size separation. Processing may be wet or dry.

Онлайн консультация

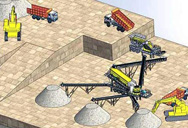

Simplified flow chart showing typical iron ore

... activities involved in mining and processing iron ore on site are shown in the flow chart in Figure 1. Ore processing ranges from simple crushing and screening methods to more...

Онлайн консультация

Iron Ore Pelletizing Process: An Overview IntechOpen

2018年7月11日 The iron ore pelletizing process consists of three main steps: Pelletizing feed preparation and mixing: the raw material (iron ore

Онлайн консультация

Iron processing Definition, History, Steps, Uses, Facts

2023年6月19日 iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting.

Онлайн консультация

Dry beneficiation of iron ore - Mineral Processing

By June 2021, it had detected iron ore reserves of 1 850 Mt with an average iron content of the mines from 56.9 % to 62.8 %. From the Jimblebar Mine (Fig. 9), so far an iron ore with 60.5 % iron content has been produced in the DSO process as “fine blends”.

Онлайн консультация

Dry beneficiation of iron ore - Mineral Processing

The haematite ore in South Africa is processed in a dry process to a HQ lump ore with 64 % iron content and a sintered fine ore with 63.5 % iron content. For fine ore beneficiation, wet processes are used. Capacity at the Minas Rio is to be increased from 26.5 Mta capacity to 28 Mta in the forthcoming years.

Онлайн консультация

Iron ore BHP

Large-scale shipping The ships we use to transport iron ore to our customers can carry around 47 Olympic-sized swimming pools worth of material. Fe The chemical symbol for iron is 'Fe'. This comes from its

Онлайн консультация

Iron processing Definition, History, Steps, Uses, Facts

2023年6月19日 iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for

Онлайн консультация

Advances in Low Grade Iron Ore Beneficiation

Low grade Beneficiation Techniques The occurrence of Indian iron ore deposits are mainly of haematite, magnetite, goethite and siderite. However, world production for iron is mostly by extensive use of haematite and magnetite as principle oxide feed.

Онлайн консультация

Iron ore mining and dressing - tec-science

2018年6月21日 The flow chart shows the basic steps of how iron ore is used to produce semi-finished products of steel. The individual process steps are explained in more detail in the following articles. Figure: From

Онлайн консультация

Iron Ore Processing - an overview ScienceDirect Topics

In India, where iron ore processing is one of the major industries, the generation of tailings is estimated to be 10-25 % of the total iron ore mined, amounting to 18 million tons per year (Das et al., 2000 ). The tailings contain silica in high percentage (40-60 %, from various locations). This makes it a suitable raw material for the ...

Онлайн консультация

Iron Processing Equipment, Process Flow, Cases

2019年8月23日 For example, the BXSTEEL adopts CTDG1516 permanent magnet dry magnetic separators to process 350~0 mm ore, the processing capacity is 600~800t/h, the waste rock yield is 12.5%, the original ore

Онлайн консультация

Our Mining Process - Iron Ore Company of Canada

The crude ore is loaded into trucks, which dump the material into the loading pockets or into the in-pit crusher located in the Luce pit.","3825":"IOC\u2019s operations are integrated across our mine and

Онлайн консультация

iron ore processing flow chart Archives - 911 Metallurgist

iron ore processing flow chart Archives - Mineral Processing Metallurgy iron ore processing flow chart Beneficiation of Iron Ore Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice.

Онлайн консультация

Simplified flow chart showing typical iron ore

... activities involved in mining and processing iron ore on site are shown in the flow chart in Figure 1. Ore processing ranges from simple crushing and screening methods to more...

Онлайн консультация

Iron processing Definition, History, Steps, Uses, Facts

2023年6月19日 Pieces of cast iron were placed on a finery hearth, on which charcoal was being burned with a plentiful supply of air, so that carbon in the iron was removed by oxidation, leaving semisolid

Онлайн консультация

Iron ore beneficiation: an overview - ScienceDirect

2023年1月1日 Flow-sheets for low-grade ore processing of different iron ore mines vary significantly; however, the underlying principle of operation is very similar. Methodology for selection of beneficiation flowsheet is already defined in the above sections. For beneficiation of coarser fraction (+1 mm), jigging is widely used.

Онлайн консультация

12.5 Iron And Steel Production - US EPA

The production of 1 ton of iron requires 1.4 tons of ore or other iron bearing material; 0.5 to 0.65 tons of coke; 0.25 tons of limestone or dolomite; and 1.8 to 2 tons of air. Byproducts consist of 0.2 to 0.4 tons of slag, and 2.5 to 3.5 tons of blast furnace gas containing up to 100 pounds (lb) of dust.

Онлайн консультация

Our Mining Process - Iron Ore Company of Canada

The crude ore is loaded into trucks, which dump the material into the loading pockets or into the in-pit crusher located in the Luce pit.","3825":"IOC\u2019s operations are integrated across our mine and

Онлайн консультация

Iron processing - Ores, Surface Mining, Sintering, and Pelletizing

Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments. Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine. The most widely distributed iron-bearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is red;

Онлайн консультация

11.23 Taconite Ore Processing

Processing of taconite consists of crushing and grinding the ore to liberate iron-bearing particles, concentrating the ore by separating the particles from the waste material (gangue), and pelletizing the iron ore concentrate. A simplified flow diagram of these processing steps is shown in Figure 11.23-1.

Онлайн консультация

Effective Processing of the Iron Ores

complex wasteless processing of high grade iron ores was evaluated. The general physical and metallurgical properties of briquettes are known: fineness, coverage rate, oil adsorption, etc. It should be mentioned that during the researches the prospect of processing iron ore with iron content 69% and more (“superconcentrate”) has been

Онлайн консультация

Iron Ore Processing - an overview ScienceDirect Topics

In India, where iron ore processing is one of the major industries, the generation of tailings is estimated to be 10-25 % of the total iron ore mined, amounting to 18 million tons per year (Das et al., 2000 ). The tailings contain silica in high percentage (40-60 %, from various locations). This makes it a suitable raw material for the ...

Онлайн консультация

iron ore processing flow chart Archives - 911 Metallurgist

iron ore processing flow chart Archives - Mineral Processing Metallurgy iron ore processing flow chart Beneficiation of Iron Ore Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practice.

Онлайн консультация

Coal Processing - Multotec

Coal processing uses physical, mechanical and/or chemical methods, to remove rocks, dirt, ash, sulphur, and other contaminants and unwanted materials to produce high-quality coal for energy in both local and export

Онлайн консультация